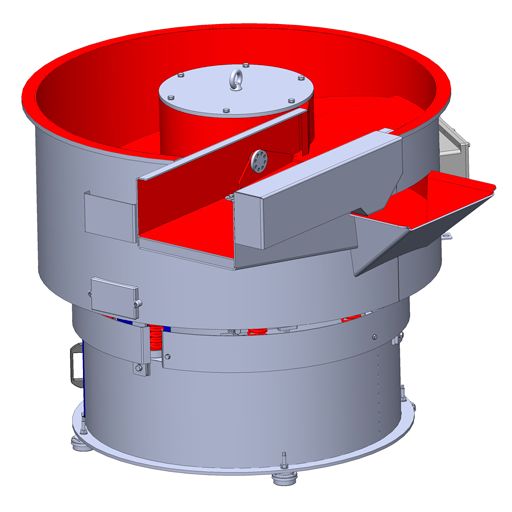

Settling & Rinsing Tanks

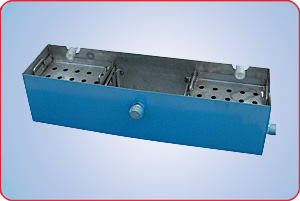

Settling Tanks are a “must have” for most mass finishing systems that are wet processing. Typically located on the floor next to the mass finishing machine, they are the collection tank receiving the spent process solution, from the machine drain , generated in the finishing process. The tank can be used for re-circulating the finishing solution with a Royson rc500 pump. The tank in combination with a submersible pump can send the solution to next step in treating the effluent prior to discharge. Rinsing tanks are also available for rinsing parts after the finishing process.

20 Gallon Settling Tank

25 Gallon Settling Tank

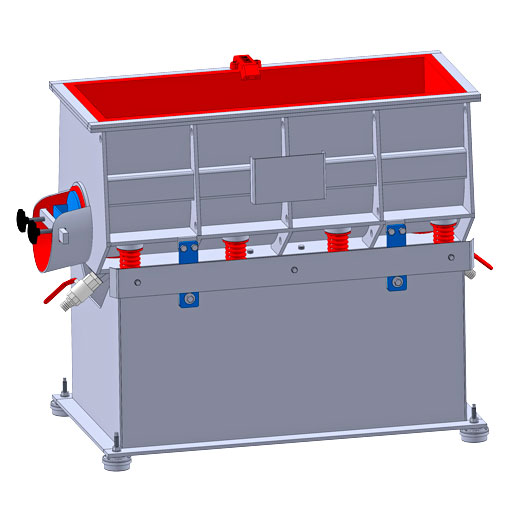

Standard Settling Tank

Heated Rinsing Tank

Tank with Lifting Lugs and Pump Platform

350 Gallon Holding Tank

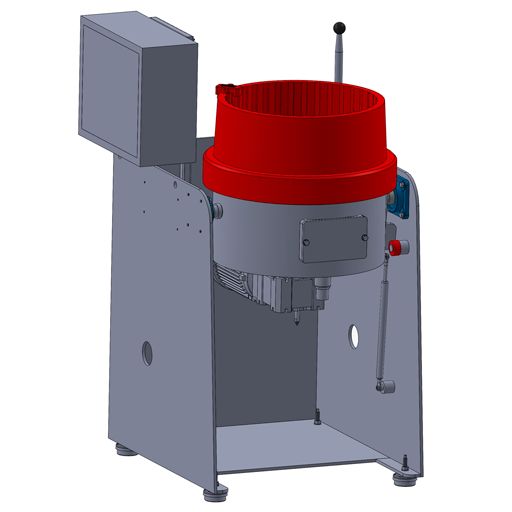

Tank with Agitator

250 Gallon Plastic Holding Tank

Royson Engineering Company

STANDARD 304 SS SETTLING TANK SPECIFICATIONS

| GALLONS | OVERALL TANK DIM. H X W X L | MAXIMUM WATER LEVEL | MATERIAL TYPE & THICKNESS | # OF CHAMBERS | # OF DAMS | FILTER PAPER TRAY | SHIP WEIGHT LBS. |

|---|---|---|---|---|---|---|---|

| 20 | 12 X 16 X 40 | 7.0” | 304 SS, .12 | 2 | 1 | STD | 105 |

| 25 | 12 X 15 X 56 | 7.0” | 304 SS, .12 | 3 | 2 | (2)STD | 150 |

| 28 | 14 X 18 X 40 | 9.0” | 304 SS, .12 | 3 | 2 | STD | 135 |

| 40 | 14 X 26 X 40 | 9.0” | 304 SS, .12 | 3 | 2 | STD | 150 |

| 68 | 16 X 32 X 45 | 11.0” | 304 SS, .12 | 3 | 2 | STD | 165 |

| 91 | 16 X 32 X 60 | 11.0” | 304 SS, .12 | 3 | 2 | STD | 195 |

- SPECIAL WIDTH, HEIGHT, AND LENGTH TANKS

- TANK LIDS

- DISCHARGE PUMPS & PUMP PLATFORMS

- ADDITIONAL PAPER TRAYS & DAMS

- FLOOR LAYOUT DRAWINGS

- OIL SKIMMERS

- IMMERSION HEATERS